For over 49 years, Polynyl Plastics has been manufacturing polyurethane products. We are suppliers of engineering grade polyurethane tyres and rollers to this industry. We offer comprehensive manufacturing of sheets, rods and tubes and take into account your specified hardness, colour and durability requirement.

Advantages of Using Polyurethane Engineering Products

-

Abrasion or resistance

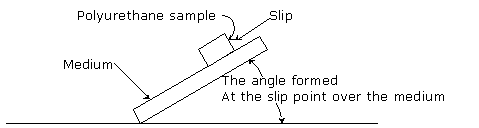

Polyurethane offers outstanding durability when compared to rubber or plastic applications. The friction properties are proportionate to the hardness and can be calculated by the surface area of the polyurethane in contact with the medium over which it is to slip multiplied by tan delta of the angle of slip point.

- Compression and elongation

These mechanical properties are the two most common demands made of polyurethane. This is where polyurethanes excel in a broad range of applications. From the flexing of a suspension bush to the compression of a stripper plate of a press tool, this definitely is an engineering product.

Punch and Die Applications:

Economic in stripping applications: Replacing ejector spring for polyurethane.

Polyurethane is oil acid resistant material giving superior life compared to rubber.

When set up with the correct compression and cycle time polyurethane will outperform springs or rubber applications.

Support pads forming inserts and compression forms molded to your specification. Moulded forms may have a metal backing or inserts moulded into the form for support or location.

Polyurethane comes in different hardness, colours, densities formulation and chemical resistance. There is a hardness and type to suit most applications. These features can be determined by the compression, deflection and cycle time determined by the process.

Polyurethane hardness range is measured with a Durometer, 2 types Shore "A" and "D" from soft; rubber band at 35 shore "A" to hard material nylon at 80 shore "D".

Polyurethane can also be used in tension, as it will stretch more than twice that of rubber.

Most applications are usually focused around 90'A' and is the most common middle grade in use. With a proper evaluation the correct hardness and compression to suit the design and cycle time of the tooling. This will give maximum tool life and produce more consistent parts.